A panel filter is a primary-stage air filter commonly used in HVAC systems, cleanrooms, and industrial ventilation. Its main purpose is to remove coarse airborne particles such as dust, pollen, and fibers from the air before it reaches sensitive equipment or secondary filters like HEPA or ULPA filters.

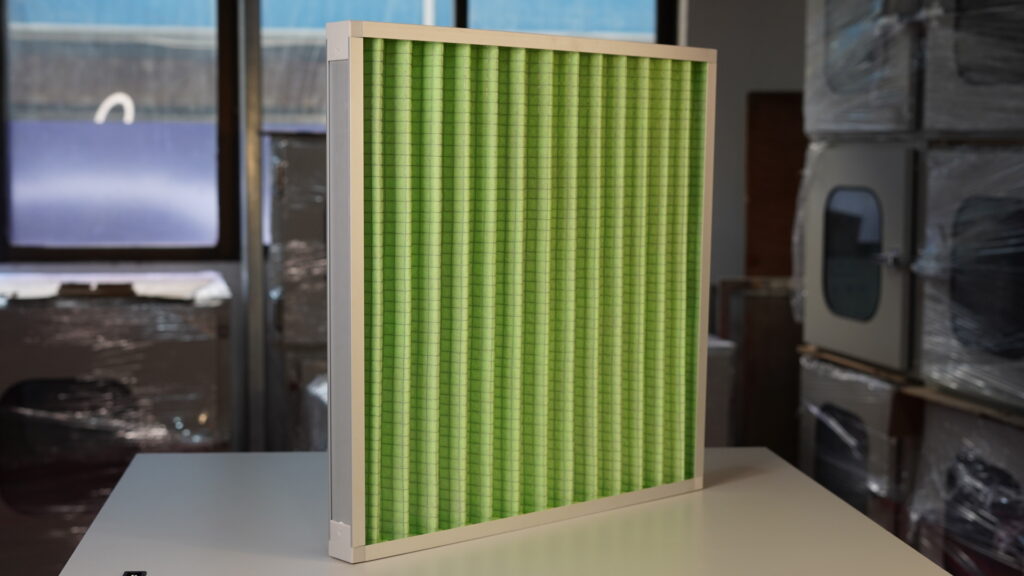

Panel filters are often flat or pleated in design, built from synthetic fiber media mounted in rigid frames made of galvanized steel, aluminum, or cardboard. They are valued for their low resistance, easy installation, and cost-effectiveness in pre-filtration environments.

2. How Do Panel Filters Work?

Panel filters function on the principle of mechanical filtration, capturing particles through a combination of physical mechanisms such as:

Inertial impaction – Large particles hit fibers and stick due to their momentum.

Interception – Medium-sized particles follow airflow but brush against filter fibers.

Diffusion – Very small particles move randomly (Brownian motion) and are absorbed into the filter media.

This multilayered filtration mechanism is commonly referenced in standard filtration theory and makes panel filters effective in removing particles between 10 and 50 microns.

3. Understanding G1 to G4 Filter Classifications

G1 Panel Filters: Basic Coarse Filtration

G1 panel filters are the most basic form of coarse air filters. They are designed to capture large particles typically above 50 microns in diameter—such as visible dust, hair, textile fibers, and large debris. G1 filters are often used in low-demand HVAC systems or as preliminary protection in environments with minimal air quality requirements. Their primary purpose is to shield equipment and ducts from bulk contaminants.

G2 Panel Filters: Light Commercial Use

G2 filters offer slightly improved filtration efficiency compared to G1, targeting particles above 20 microns. These filters are commonly used in light commercial environments and general ventilation systems. While they don’t provide fine particulate control, they serve well in protecting fans, coils, and heat exchangers from clogging, helping to maintain stable airflow and reduce maintenance costs.

G3 Panel Filters: Pre-Filtration for F-Class Filters

G3 panel filters are suitable for capturing particles down to approximately 10 microns. They are typically used as pre-filters in systems that also include medium or high-efficiency filters (e.g., F5–F9 or HEPA stages). G3 filters are ideal for environments with moderate airborne particulate matter—such as manufacturing areas, warehouse ventilation, and industrial air intakes.

G4 Panel Filters: High-Efficiency Coarse Filters

G4 panel filters provide the highest level of performance within the coarse filter category, removing up to 85–90% of particles greater than 5 microns. These filters are widely used in cleanroom pre-filtration stages, pharmaceutical and electronics production areas, and high-demand HVAC systems. G4 filters are also frequently employed in ISO Class 8 cleanroom environments as the first stage of air purification.

4. Pleated vs. Flat Panel Filters

There are two main structural variants:

Flat Panel Filters: Basic, low-resistance design; suitable for light-load environments or tight budgets.

Pleated Panel Filters: Media is folded accordion-style, increasing surface area and dust-holding capacity without increasing footprint. Ideal for higher airflow systems.

Pleated panel filters offer better filtration per surface area and are widely used in systems that require more consistent performance and longer replacement intervals.

5. Industry Standards: MERV, ISO, and Testing Protocols

Panel filters are often rated by the MERV (Minimum Efficiency Reporting Value) system, especially in North America. MERV 1–4 generally covers G1–G4-grade panel filters:

MERV 1–4: Captures particles >10µm (pollen, dust, lint)

MERV 5–8: Captures particles 3–10µm (mold spores, pet dander)

Additionally, ISO 16890 has become the global standard for classifying air filters based on their ability to remove PM1, PM2.5, and PM10 particulate matter.

For engine and compressor air filtration, ISO 5011:2014 governs laboratory testing procedures (view standard).

6. Applications of Panel Filters

Panel filters are used across a wide range of industries:

HVAC systems in commercial buildings and shopping malls

Electronics assembly for pre-cleanroom airflow control

Pharmaceutical processing, especially for packaging and storage areas

Food and beverage production zones requiring basic air cleanliness

Power plants and paint booths, where coarse filtration is sufficient

Their role is especially critical in multistage filtration systems, where they act as a sacrificial first line of defense.

7. When to Replace a Panel Filter

Replacement frequency depends on:

Airborne contamination level

Filter grade

System runtime and airflow speed

Most G1–G4 panel filters need replacement every 1–6 months. To optimize maintenance, many industrial setups include differential pressure gauges or alarms to monitor resistance buildup.

8. Conclusion: Choosing the Right Panel Filter

When selecting a panel filter, consider:

Required filtration level (G1–G4)

Airflow and pressure drop tolerance

Frame and media material compatibility

Application type: residential, commercial, or industrial

Panel filters may be simple, but they are foundational to maintaining efficient, hygienic, and cost-effective air handling systems.

For long-term performance, always pair the right panel filter with an appropriate maintenance schedule and airflow monitoring strategy.

✅ Need a customized panel filter for your facility?

We provide OEM solutions tailored to your HVAC or cleanroom system. [Contact us now →]