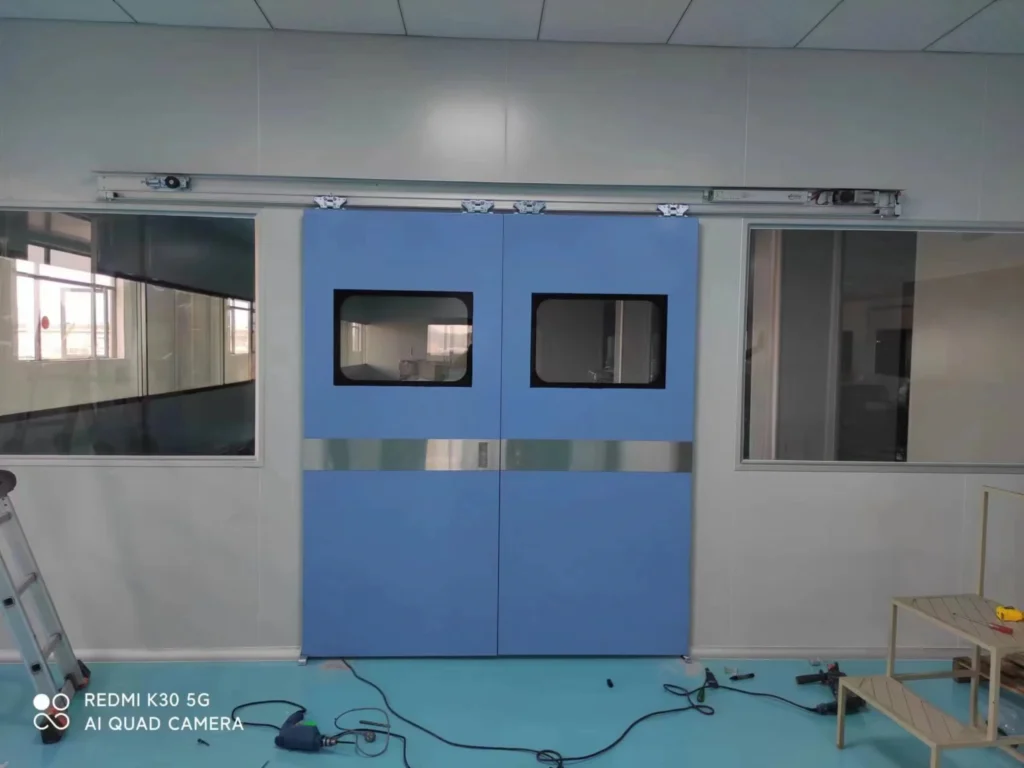

Cleanroom Doors – Clean Steel & PVC High-Speed Options

We offer two high-performance cleanroom door solutions designed to meet ISO and GMP standards: clean steel doors and PVC quick rolling doors. Each model supports particle control, pressure integrity, and access efficiency in pharmaceutical, biotech, and electronics facilities.

Cleanroom Door Specifications for ISO-Class Environments

Our cleanroom doors are engineered for controlled environments that require reliable sealing, hygienic operation, and compatibility with ISO 5–8 cleanroom standards. Available in swing, sliding, and high-speed PVC types, each door is designed for durability, ease of cleaning, and integration with wall systems.

We offer multiple material options, interlocking systems, and automatic control configurations to meet the specific requirements of pharmaceutical, biotech, electronics, and food-grade facilities.

| Specification | Detail |

|---|---|

| Available Types | Swing door / Sliding door / High-speed PVC door |

| Materials | Powder-coated steel / Stainless steel 304 / 316 / HPL |

| Cleanroom Rating | Suitable for ISO Class 5–8 / GMP-compliant |

| Door Leaf Thickness | 40–60 mm (standard), customized available |

| Seal Type | EPDM / Silicone gasket (air-tight options available) |

| Vision Panel | Double-layer tempered glass or acrylic with flush integration |

| Operation Mode | Manual, automatic with radar sensor or access control |

| Frame Integration | Compatible with cleanroom sandwich panels or masonry walls |

| Accessories | Interlock systems, access control, electric lock, push button, warning light |

All technical specifications listed are typical values and subject to change. For precise configuration and compliance guidance, we recommend consulting with our cleanroom door specialists.

Cleanroom Doors for Contamination Control

Our cleanroom doors are built for ISO-class environments, offering airtight sealing, smooth access, and easy integration with wall systems. Available in manual or automatic, swing or sliding, and PVC high-speed configurations.

✅ Stainless steel or powder-coated finish

✅ Compatible with interlocks and cleanroom panels

✅ Supports ISO 5–8 clean zones (GMP-compliant)

✅ Custom sizing, window options, and access control available

Ideal for pharmaceuticals, electronics, biotech, and clean logistics applications.

Optimized Version (for Cleanroom Equipment Manufacturers)

Our cleanroom doors, air showers, and laminar flow systems are trusted by professionals across the pharmaceutical, semiconductor, biotechnology, electronics, and food processing industries. We offer fully customized airflow and entry solutions that meet ISO and GMP standards for critical environments.

Need help choosing the right system? Our team can recommend the ideal model based on your cleanroom class, workflow, and industry requirements.

Buyer-Focused FAQ – Cleanroom Doors

1. Can I request custom sizes and configurations?

Yes. All doors are made to order. You can customize width, height, window size, control system, and sealing requirements.

2. Do your doors meet ISO and GMP standards?

Absolutely. Both steel and PVC models are suitable for ISO Class 5–8 environments, with options for hermetic sealing and interlocking.

3. What’s the difference between clean steel doors and PVC rolling doors?

Steel doors are ideal for low-traffic, high-sealing environments.

PVC rolling doors are faster and better for logistics-heavy areas.

4. How are the doors controlled?

Steel doors can be manual or automated. PVC rolling doors support motion sensors, buttons, access control, and remote triggering.

5. How are doors shipped internationally?

All doors are export-packed in wooden crates with protective film and edge guards. Installation manuals and hardware are included.

Looking for the Right Cleanroom Door for Your Project?

From durable clean steel doors to high-speed PVC rolling doors, we provide ISO/GMP-compliant solutions tailored to your cleanroom needs.