Pass Box Manufacturer in China for Cleanroom Contamination Control

As a professional pass box manufacturer based in China, we provide a full range of cleanroom pass boxes designed for contamination-free material transfer across pharmaceutical, biotech, and electronics industries.

Our product lineup includes:

Static pass boxes for basic material transfer between clean areas

Dynamic pass boxes with HEPA filters and internal air circulation

Air shower pass boxes for particulate decontamination of surfaces

Stainless steel pass boxes for durable cleanroom installations

Options include wall-mounted, floor-standing, and sliding-door designs

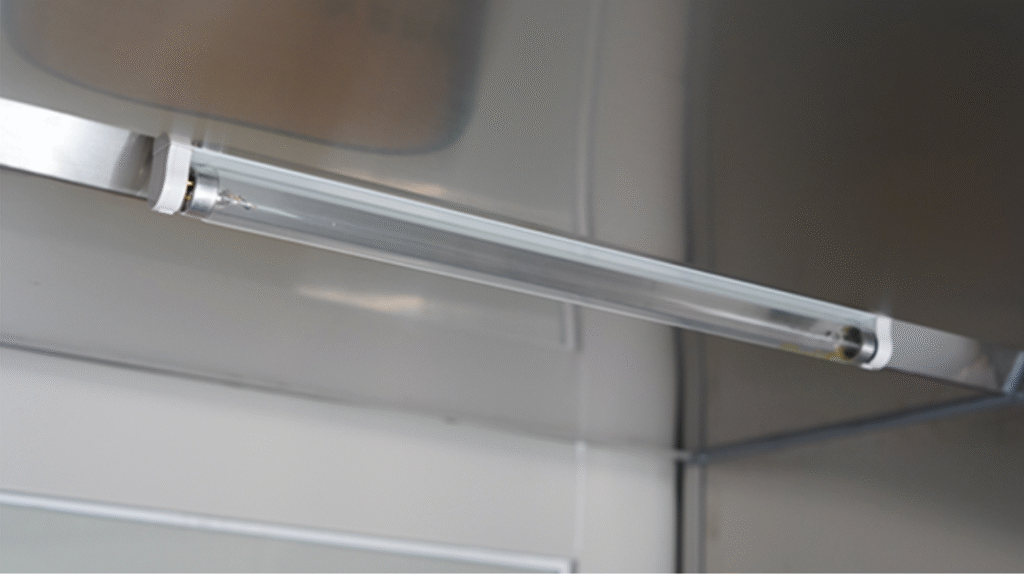

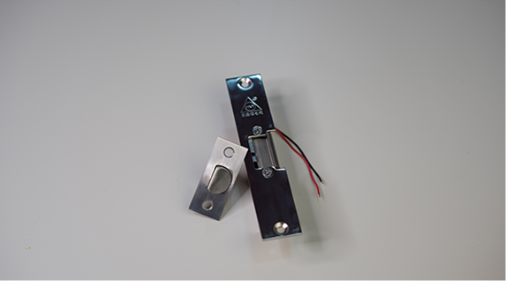

All models are manufactured in compliance with ISO/GMP standards, and can be customized with UV lamps, interlocking systems, pressure gauges, and more to suit your project needs.

Pass Box Specifications

Our pass boxes are precision-built for controlled cleanroom environments, helping to maintain pressure differentials and minimize cross-contamination during material transfer.

We offer static, dynamic, and air shower pass box options to support ISO 5–8 cleanroom zones. Each unit is designed for durability, easy cleanability, and full GMP/ISO compliance—making them essential for sterile production, pharmaceutical logistics, and critical material flow control.

Need help choosing the right model? Contact us for size guidance, filtration configurations, and interlock system integration.

| Model | External Dimensions (L×W×H) | Material | Door Type | Filtration | Cleanroom Level |

|---|---|---|---|---|---|

| Static Pass Box | 600×600×600 mm (customizable) | Powder-coated steel / SS304 | Manual swing (interlock) | None (air-tight interlock only) | ISO 7–8 |

| Dynamic Pass Box | 700×700×700 mm (customizable) | Stainless steel 304 / 316 | Manual or automatic (electronic interlock) | HEPA H14 + Centrifugal Blower | ISO 5–6 |

| Air Shower Pass Box | 800×800×900 mm (customizable) | Stainless steel 304 / powder-coated | Automatic door + dual interlock | HEPA H13 + High-velocity nozzles | ISO 5+ |

All technical specifications listed are typical values and subject to change. For precise configuration and compliance guidance, we recommend consulting with our cleanroom door specialists.

Engineered Pass Box Solutions by a Trusted Manufacturer

Our cleanroom pass boxes are precision-built transfer chambers that allow safe material movement between areas of different cleanliness levels. Designed and manufactured by an experienced pass box manufacturer, each unit is constructed from stainless steel or powder-coated steel with options for interlocking doors, UV sterilization, and HEPA-filtered airflow.

We offer various models, including static pass box, dynamic pass box, and air shower pass box systems—tailored for pharmaceutical, electronics, and GMP cleanroom environments. Custom features such as vertical sliding doors, touchscreen controls, and wall-mounted installation are also available for OEM/ODM needs.

As a reliable pass box manufacturer, we ensure ISO-compliant design, fast production, and flexible global delivery.

Air Shower Room Options

Pass Box Systems for Cleanroom Industry Applications

Our pass boxes are trusted by cleanroom operators in pharmaceuticals, biotechnology, semiconductors, and food-grade production. As a professional pass box manufacturer, we offer static, dynamic, and air shower pass boxes engineered to meet ISO and GMP standards.

Whether for sterile material transfer, product hand-off between controlled areas, or contamination-free workflows, our pass box systems ensure reliability and compliance across critical industries.

Frequently Asked Questions (FAQ)

Q1: Can I customize the size, door type, or filter configuration?

Yes. We support full OEM customization. You can choose the size, material (e.g. stainless steel 304 or 316), type of interlock, manual or automatic doors, and HEPA or ULPA filters. Let us know your project specs and we’ll tailor the solution.

Q2: What is the minimum order quantity (MOQ)?

For standard models, MOQ is 1 unit. For custom builds, MOQ may vary based on design complexity. We’re flexible for trial orders and small-batch cleanroom projects.

Q3: How long is your lead time for delivery?

Standard models: 7–10 working days

Customized models: 15–20 working days

We ship worldwide by sea, air, or express—DDP, CIF, and FOB terms available.

Q4: Do your pass boxes come with certifications?

Yes. All models comply with ISO 14644 standards. We provide CE documentation, HEPA filter test reports, material traceability, and optional FAT protocols upon request.

Q5: How often should I replace the HEPA filter?

HEPA filters should be replaced every 6–12 months, depending on usage frequency and cleanliness standards. We also provide easy-access filter housings to simplify maintenance.

Need a Reliable Pass Box Solution?

Tell us your cleanroom layout and contamination control requirements—we’ll recommend the right static, dynamic, or air shower pass box for your operation.