Manufacturing Cleanroom Solutions

High-Efficiency, Contamination-Free Environments for Advanced Manufacturing

What Is a Manufacturing Cleanroom?

A Manufacturing Cleanroom is a highly controlled environment used to minimize particulate, microbial, and electrostatic contamination in precision manufacturing processes. These cleanrooms are designed in accordance with ISO 14644, GMP, and industry-specific standards to support high-quality production.

Key Benefits of a Manufacturing Cleanroom

Deploying cleanroom environments in manufacturing lines offers major benefits:

Where Manufacturing Cleanrooms Are Commonly Used

Our Cleanroom Services & Advantages

We offer turnkey cleanroom solutions tailored to your manufacturing process:

- ISO-Class Design (ISO 5–8) with airflow and material flow layout planning

- Electrostatic Discharge (ESD) Protection Systems

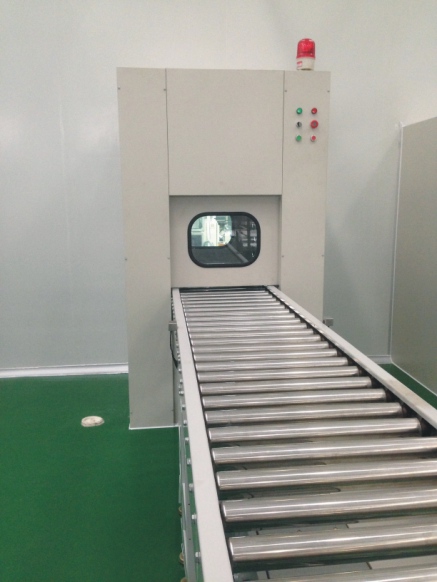

- Cleanroom-Compatible Equipment & Automation Integration

- Modular Panels, Easy-to-Clean Antistatic Walls & Ceilings

- Pass Boxes, Air Showers, and Material Transfer Solutions

- Fast Deployment & 24/7 Global Support

- System Validation & Certification Services

FAQs – Manufacturing Cleanroom

Q1: What ISO class is required for precision manufacturing?

Most facilities require ISO Class 5–7 depending on product sensitivity (e.g., ISO 5 for semiconductor, ISO 7–8 for plastic assembly).

Q2: How is a manufacturing cleanroom different from a lab cleanroom?

Manufacturing cleanrooms prioritize layout for machinery, material flow, and static control; lab cleanrooms emphasize sterile handling and human procedures.

Q3: Can cleanroom designs integrate with production lines?

Yes, our modular systems can integrate seamlessly with your machines and conveyors for smooth operations.

Q4: How long does installation take?

A 200㎡–500㎡ cleanroom can typically be built in 4–6 weeks, including filtration, panels, and air circulation systems.