Modular Cleanroom Manufacturer in China for Cleanroom Contamination Control

Modular cleanroom are pre-engineered, self-contained environments that provide ISO-classified air cleanliness within a flexible and scalable framework. Unlike traditional cleanroom builds, modular designs use prefabricated wall panels, ceiling systems, and integrated HVAC solutions, enabling:

Rapid setup – cut installation time by 40–60%

Custom configurations – ISO 5–8 compliant

Cost efficiency – lower construction and operational costs

Future expansion – reconfigurable or relocatable layout

As an experienced Modular Cleanroom Manufacturer, we specialize in Hardwall and Softwall systems tailored to your industry’s compliance and environmental control needs.

Modular Cleanroom Specifications

Our modular cleanrooms are built to meet ISO 5–8 standards, with fast installation and long-term performance in mind. All components are prefabricated for clean assembly and future scalability.

Key Features:

Wall Panels: Powder-coated steel, PVC, or HPL; optional aluminum honeycomb core

Frame System: Aluminum or steel, sealed and non-shedding

Ceiling Grid: Compatible with HEPA/ULPA FFUs and LED fixtures

Doors & Windows: Air-tight cleanroom doors and flush-mounted viewing windows

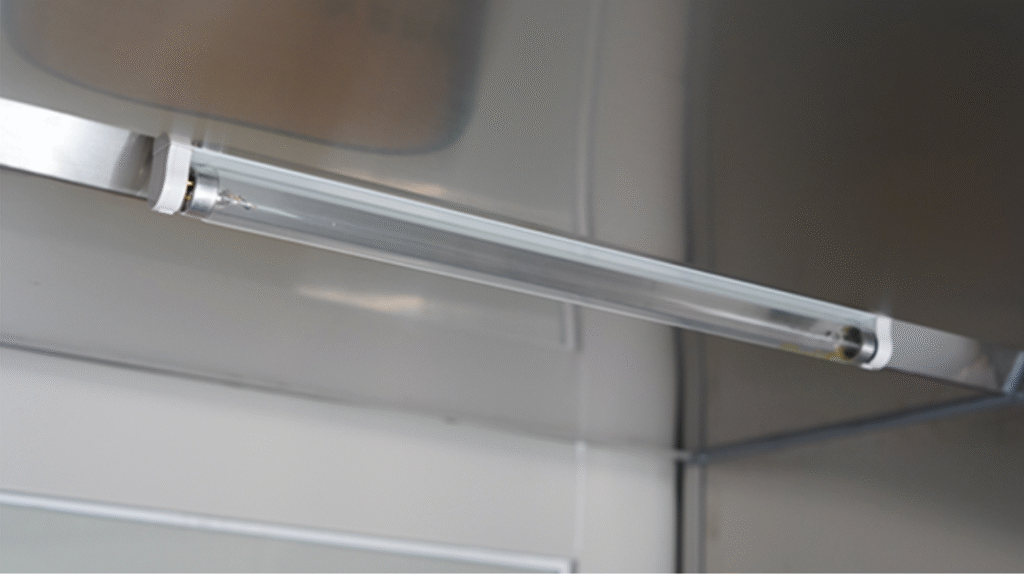

Lighting: ISO-rated LED lights, energy efficient and easy to maintain

Filtration: HEPA 99.99% @ 0.3μm; ULPA optional

HVAC Integration: Optional temperature, humidity, and pressure control

Flooring Options: ESD vinyl or epoxy finishes

All systems are customizable and pre-tested, ensuring rapid deployment and GMP compliance.

| Feature | Hardwall Modular Cleanroom | Softwall Modular Cleanroom |

|---|---|---|

| ISO Cleanliness Levels | ISO 5–8 | ISO 7–8 |

| Panel Materials | Aluminum Honeycomb, PVC, HPL | Anti-static PVC curtains |

| Frame Structure | Powder-coated Steel / Aluminum | Stainless Steel or Aluminum Tubes |

| Ceiling System | T-bar with HEPA/ULPA Filter Units | Suspended frame with filter units |

| Lighting | LED Flush Mount (Cleanroom Rated) | LED or T5 Tube |

| Filtration | HEPA 99.99% @ 0.3μm / ULPA optional | HEPA standard |

| Temperature & Humidity | Optional HVAC Integration | Optional HVAC |

| Cleanroom Height | Standard: 2.5–3m; Customizable | Standard: 2.3–2.8m |

| Installation Time | 7–15 Days | 3–7 Days |

All technical specifications listed are typical values and subject to change. For precise configuration and compliance guidance, we recommend consulting with our cleanroom door specialists.

Why Choose Us as Your Modular Cleanroom Manufacturer?

ISO & CE Certified Production

Custom Design for Site & Process Fit

Turnkey Delivery – Design, Manufacture

GMP, FDA, and ISO Compliance Guidance

Export-Ready with Global Support

Whether you need a compact ISO 8 clean booth or a full-scale ISO 5 hardwall suite, our team offers hands-on consultation, fast delivery, and full post-sale support.

Modular Cleanroom Options

Modular Cleanroom Systems for Cleanroom Industry Applications

Frequently Asked Questions (FAQ)

Q1: How long does it take to install a modular cleanroom?

Most softwall cleanrooms can be installed within 3–5 days, and hardwall systems in 7–15 days, depending on the size and complexity.

Q2: Can the cleanroom be expanded later?

Yes, modular cleanrooms are designed for easy expansion or relocation. Panels, doors, and ceiling systems can be reconfigured with minimal disruption.

Q3: What ISO cleanroom classes do you offer?

We support ISO 5, ISO 6, ISO 7, and ISO 8 configurations, with appropriate HEPA/ULPA filter layouts and validation protocols.

Q4: Do you provide HVAC and air handling units?

Yes, we offer full HVAC integration for temperature and humidity control, with optional AHU + FFU packages.

Q5: What kind of certifications do your cleanrooms comply with?

Our cleanroom systems meet international GMP, ISO 14644-1, and CE standards. We can also assist in validation and third-party certification.

Need a Reliable Modular Cleanroom Solution?

Have a project in mind? Whether it’s a sterile production room or a temperature-controlled lab, we can design a cleanroom that fits your space, compliance, and budget.