Laminar Flow Benches for Cleanroom and Laboratory Applications

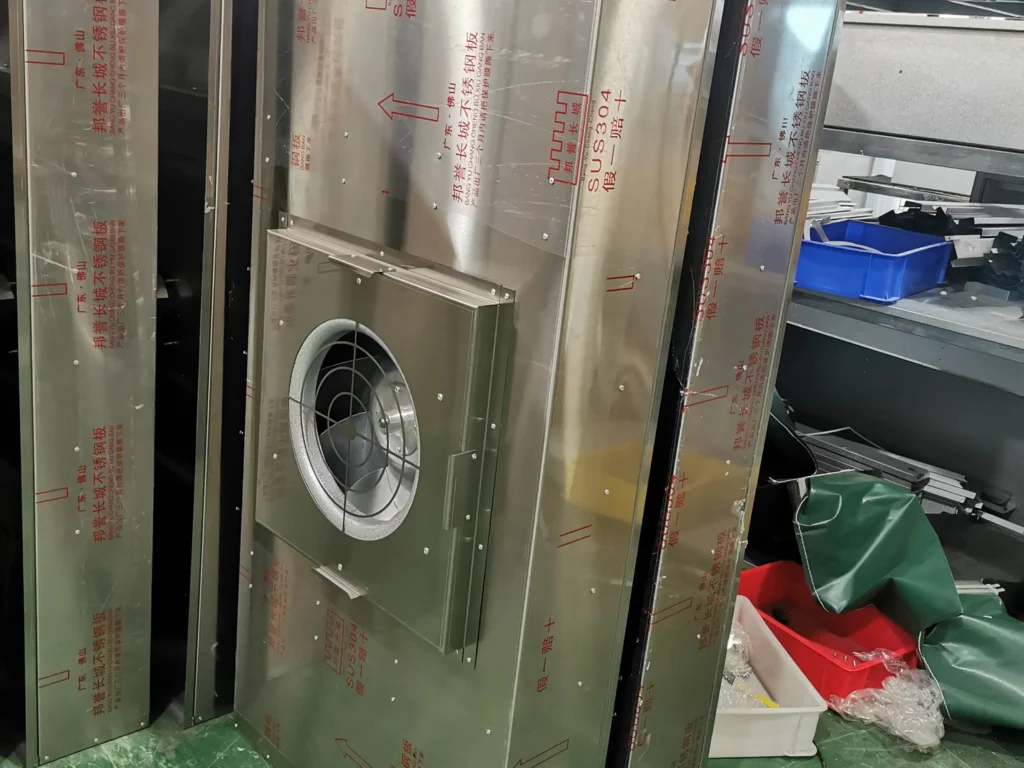

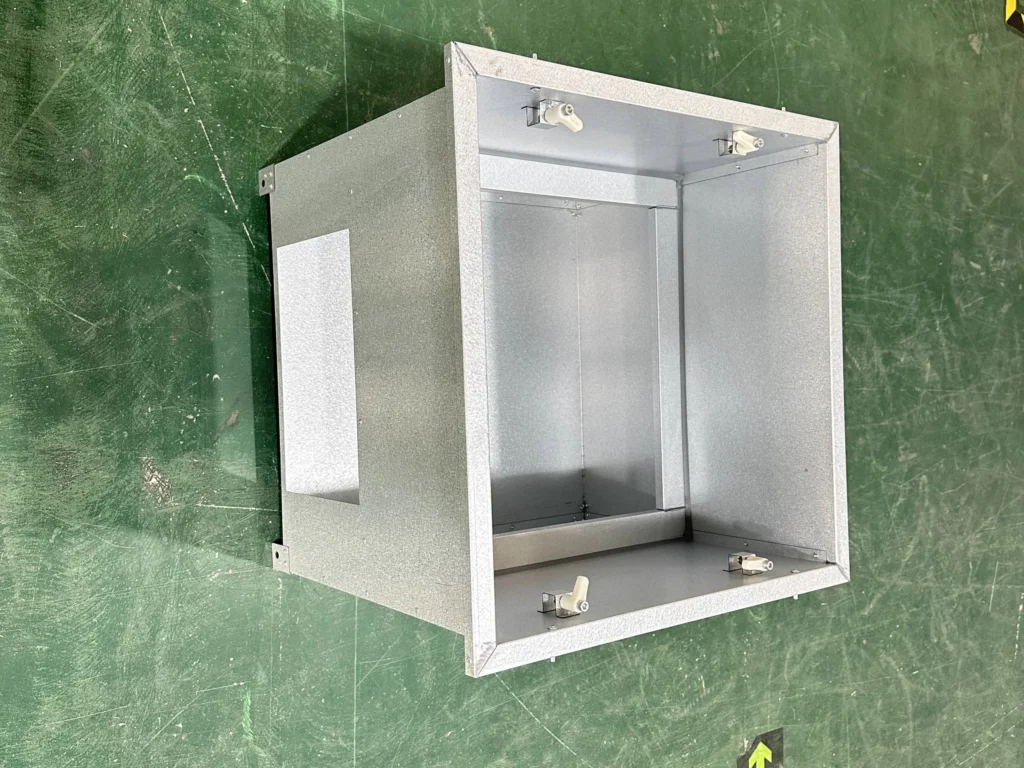

Laminar flow benches provide a controlled environment for contamination-sensitive processes by directing unidirectional, filtered air over the workspace. Available in vertical and horizontal configurations, these benches ensure ISO-class clean airflow, making them essential for labs, cleanrooms, and production environments.

Each bench is designed for particle-sensitive operations such as sample preparation, electronics assembly, and pharmaceutical handling.

Which Laminar Flow Bench Is Right for Your Cleanroom?

Choosing the right laminar flow bench can significantly improve your cleanroom operations, product integrity, and compliance with ISO standards. Whether you’re working in a pharmaceutical lab, electronics assembly line, or packaging sterile items, our benches are built to keep your workspace particle-free and process-safe.

We offer both vertical and horizontal flow benches, with HEPA/ULPA filters and ISO Class 5–8 support. Not sure what to choose? Check the typical use cases below—or contact us for a tailored recommendation.

| Cleanroom Class | Filter Grade | Typical Use Case |

|---|---|---|

| ISO 5 | ULPA U15/U16 | Semiconductor cleanrooms, nano-electronics |

| ISO 6 | HEPA H14 | Pharmaceutical clean zones, IV prep environments |

| ISO 7 | HEPA H13/H14 | Biotech labs, medical equipment production |

| ISO 8 | HEPA H13 | General cleanroom packaging, food-grade facilities |

Industries We Serve

Our laminar flow benches and cleanroom equipment are trusted by professionals in pharmaceuticals, semiconductors, precision electronics, biotechnology, food processing, and new energy sectors. We offer tailored airflow solutions to meet strict cleanliness standards across your production, packaging, and research environments.

Need industry-specific guidance? Our team can recommend the right model for your application.

Frequently Asked Questions

1. How do I choose between a vertical and horizontal laminar flow bench?

The right choice depends on your workspace layout and application:

Vertical benches are better for space-saving and clean airflow from top to bottom.

Horizontal benches are easier for manual operations like wiring or tool work, but air flows toward the user, which may not be ideal for all materials.

If you’re unsure, send us your use case—we’ll recommend the right model.

2. Can I request a custom size or configuration?

Yes. We support full OEM/ODM customization, including:

Bench size (width/depth/height)

HEPA or ULPA filter options

Work surface materials (SS304, powder-coated steel, etc.)

Add-ons like UV lights, sockets, digital displays

We regularly produce custom benches for cleanroom contractors and lab equipment distributors.

3. Do you provide CE or ISO certifications?

Absolutely. All units can be supplied with:

CE certificate

ISO 14644 test reports

HEPA filter validation report

Electrical safety compliance (upon request)

Let us know if you need documentation for local registration or tenders.

4. What is your minimum order quantity (MOQ)?

For standard models, MOQ is 1 unit.

For customized OEM models, MOQ varies based on complexity. We’re flexible for first-time orders and trial runs.

5. How are the benches packaged and shipped?

Benches are shipped fully assembled or flat-packed (if oversized), with:

Protective film and foam

Export-grade wooden crate

Labeling and inspection sheet

We arrange FOB, CIF, or DDP shipping terms to your location.

7. Do you offer after-sales support and spare parts?

Yes. We offer:

Online support for installation or maintenance

Spare HEPA filters, fans, and accessories

Long-term partner programs for distributors

Need a Reliable Laminar Flow Bench for Your Project?

Explore vertical and horizontal models, or request a customized solution tailored to your cleanroom or lab environment.