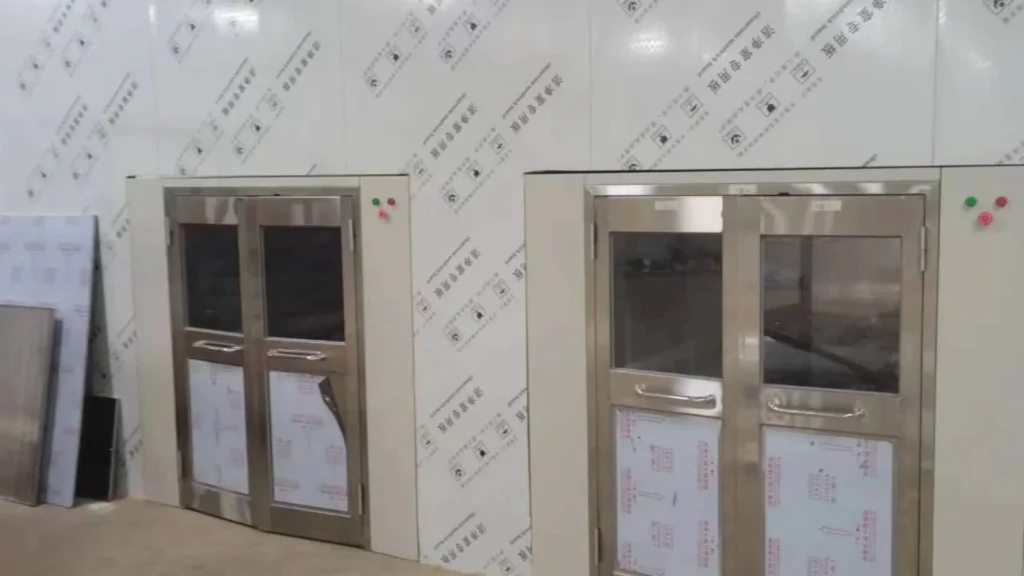

Cargo Air Shower Systems for Cleanroom Material Entry

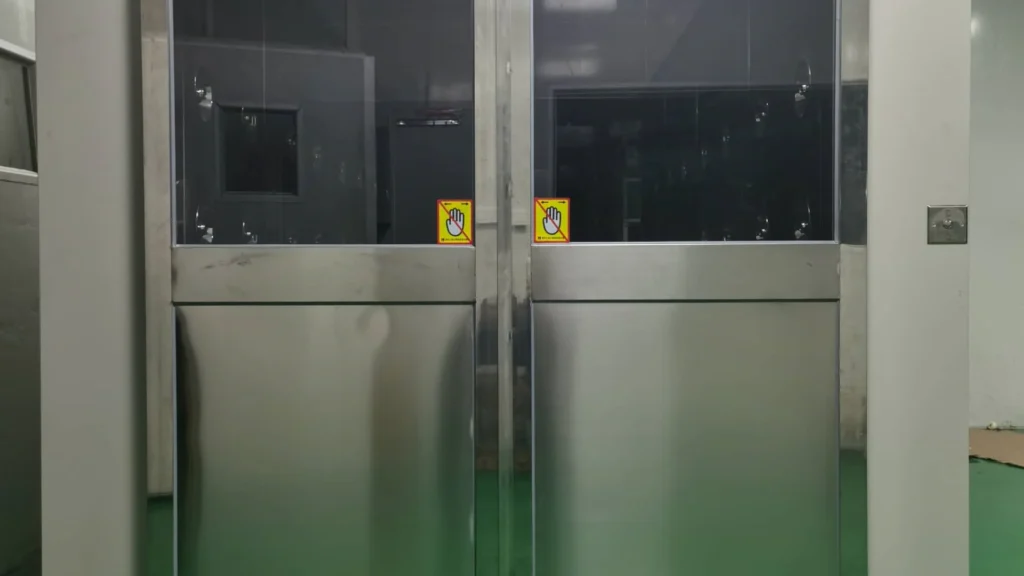

A cargo air shower is an enclosed system designed to remove surface particles from large items like trolleys, pallets, equipment, and materials before they enter a cleanroom. Using high-velocity filtered air jets and interlocked doors, cargo air showers reduce contamination risks and maintain ISO-classified environments.

As a trusted cleanroom air shower manufacturer, we offer fully customizable cargo air shower systems for a wide range of industries including pharmaceuticals, electronics, and food processing.

Cargo Air Shower Specifications for Cleanroom Material Entry

Our cargo air shower systems are designed to decontaminate pallets, carts, and equipment before entering ISO-classified cleanrooms. Using high-velocity HEPA-filtered air jets and automatic door interlocks, these units effectively remove surface particles and reduce cross-contamination risks. As a trusted cargo air shower manufacturer, we provide customizable solutions to meet the specific requirements of pharmaceutical, semiconductor, and food-grade industries — including adjustable airflow, door types, and smart control panels.

| Specification | Detail |

|---|---|

| External Dimensions | 2000×2000×2100 mm (Custom sizes available) |

| Air Velocity | ≥ 22 m/s |

| Filter Type | HEPA H13 (99.99% @ 0.3μm) |

| Blower Power | 1.1–2.2 kW (based on model size) |

| Material | Powder-coated steel / Stainless steel (304/316) |

| Door Type | Manual swing / automatic sliding |

| Control System | Touchscreen with programmable cycle time |

Cargo Air Shower Systems for Cleanroom Material Entry

Our cargo air shower systems are designed to remove surface dust and particles from carts, pallets, and equipment before they enter cleanroom environments. As a professional cargo air shower manufacturer, we engineer each unit to meet ISO cleanroom standards for contamination control. Whether you’re managing a pharmaceutical facility, electronics workshop, or food-grade production line, our systems ensure clean and efficient material entry decontamination. OEM customization, wide door access, and HEPA filtration are all available to match your operational needs.

Frequently Asked Questions About Cargo Air Showers

1. What is a cargo air shower?

A cargo air shower is a self-contained chamber equipped with high-velocity filtered air jets, used to remove surface particles from carts, pallets, equipment, or raw materials before they enter a cleanroom or controlled environment.

2. What industries use cargo air showers?

Cargo air showers are commonly used in:

Pharmaceutical and biotech facilities

Semiconductor and electronics factories

Food processing clean zones

Medical device manufacturing

Logistics entry points for cleanrooms

3. How is a cargo air shower different from a personnel air shower?

While personnel air showers are designed for people, cargo air showers are built with larger doors and reinforced structures to accommodate material handling equipment like pallet jacks and carts. Airflow is often stronger and the chamber larger.

4. Can cargo air showers be customized?

Yes. We offer OEM customization for dimensions, door types (manual, automatic, sliding), HEPA filter grade, number of blowers, and even touchscreen control systems.

5. How often do the filters in a cargo air shower need to be changed?

HEPA filters typically last 6–12 months depending on the environment and usage frequency. We recommend regular inspections and replacement when the airflow or filtration efficiency drops.

Ready to Buy a Cargo Air Shower?

Fast production, stable quality, and global delivery. Let’s get started.