Medical Device Cleanroom Solutions

Certified Cleanroom Systems for Safe and Compliant Medical Device Manufacturing

What Is a Medical Device Cleanroom?

A Medical Device Cleanroom is a highly controlled production environment designed to prevent contamination during the manufacturing, assembly, and packaging of medical devices. These cleanrooms adhere to strict regulations such as ISO 14644, GMP, and FDA 21 CFR Part 820 to ensure product safety and compliance.

Key Benefits of a Medical Device Cleanroom

Integrating cleanroom environments into your medical device production ensures

Where Medical Device Cleanrooms Are Commonly Used

Our Cleanroom Services & Advantages

As a trusted provider of cleanroom systems, we offer tailored solutions for medical device manufacturers:

- ISO Class 5–8 Cleanroom Design (based on device classification)

- FDA & GMP-Compliant Modular Cleanroom Construction

- Antibacterial, Sterilizable Wall and Ceiling Panels

- HEPA/ULPA Filtration Systems for Microbial Control

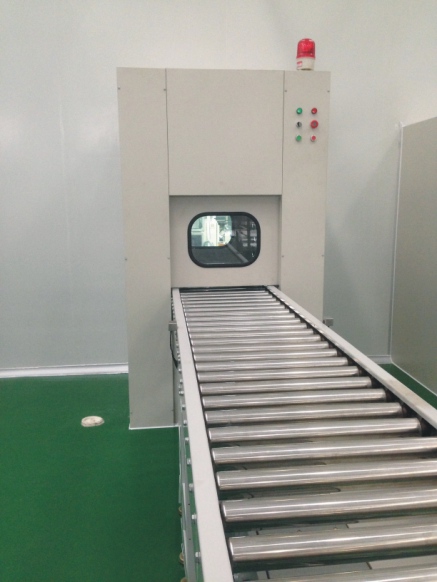

- Pass Boxes, Gowning Rooms & Air Showers

- Support for Validation, Documentation & Audits

- On-Site Installation and 24/7 After-Sales Support

FAQs – Medical Device Cleanroom

Q1: What ISO class is required for medical device production?

Typically ISO Class 7 or 8 for general production, and ISO Class 5–6 for sterile or implantable devices.

Q2: Can your cleanrooms support FDA audits?

Yes. Our systems are designed with documentation and validation support for FDA, GMP, and ISO 13485 compliance.

Q3: How are cleanrooms sterilized in device production?

Surfaces are disinfected using validated cleaning protocols; positive pressure, HEPA filters, and gowning control further reduce risks.

Q4: How long is the installation period?

For a 100–300㎡ modular cleanroom, installation typically takes 3–5 weeks including system testing and commissioning.