Laboratory Cleanroom Solutions

Controlled, Compliant, and Safe Clean Environments for Scientific Excellence

What Is a Laboratory Cleanroom?

A Laboratory Cleanroom is a controlled environment designed to maintain extremely low levels of airborne particles, temperature, humidity, and microbial contamination. It ensures the integrity of sensitive research, testing, and production processes in compliance with ISO 14644, GMP, and GLP standards.

Key Benefits of a Laboratory Cleanroom

Laboratory cleanrooms offer crucial benefits for research institutions, biotech companies, and pharmaceutical facilities:

Where Laboratory Cleanrooms Are Commonly Used

Our Cleanroom Services & Advantages

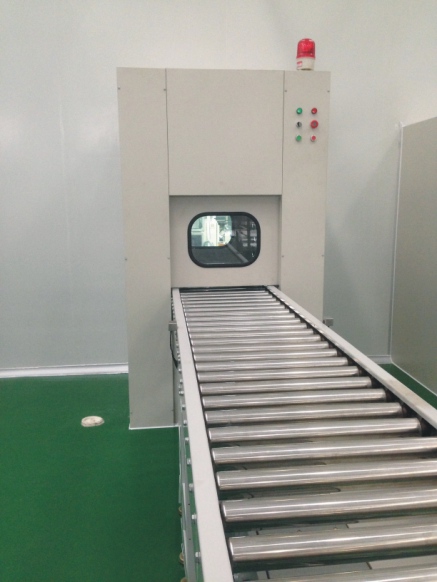

As a leading Cleanroom Manufacturer, we provide turnkey cleanroom solutions tailored to food processing needs:

- Custom Design & Layout compliant with ISO & GMP standards

- Modular Panel Systems with chemical-resistant finishes

- HEPA/ULPA Air Filtration for ISO Class 5–8 Environments

- ESD-Safe and Easy-to-Disinfect Wall & Ceiling Surfaces

- Pass Boxes, Laminar Flow Cabinets & Biosafety Zones

- Rapid Assembly & Global Technical Support

- Complete Documentation for Validation & Certification

FAQs – Laboratory Cleanroom

Q1: What ISO class do laboratories typically require?

Most lab cleanrooms range from ISO Class 5 to 8, depending on the application (e.g., pharmaceutical testing, nanotech, microbiology).

Q2: What’s the difference between a lab cleanroom and a standard lab?

Cleanrooms feature controlled airflow, filtered air systems, and strict environmental control, while regular labs may lack particle and microbial regulation.

Q3: Are cleanroom garments required in laboratory cleanrooms?

Yes. Gowning protocols are essential to prevent contamination, especially in biosafety or pharmaceutical R&D labs.

Q4: How long does installation take for a lab cleanroom?

A 100–300㎡ cleanroom typically requires 3–5 weeks for installation, depending on design complexity and required ISO class.