Pharmaceutical Cleanroom Solutions

GMP-Compliant Cleanroom Systems for Sterile and Non-Sterile Drug Manufacturing

What Is a Pharmaceutical Cleanroom?

A Pharmaceutical Cleanroom is a controlled environment specifically designed to eliminate contaminants during the production, formulation, filling, and packaging of pharmaceutical products. These facilities meet stringent regulatory requirements such as GMP, FDA 21 CFR Part 210/211, and ISO 14644 to ensure drug safety, purity, and consistency.

Key Benefits of a Pharmaceutical Cleanroom

Establishing a cleanroom in your pharma production line ensures:

Where Pharmaceutical Cleanrooms Are Commonly Used

Our Cleanroom Services & Advantages

We offer turnkey pharmaceutical cleanroom solutions that comply with the most rigorous global regulations:

- ISO Class 5–8 / EU GMP Grade A–D Cleanroom Design

- Modular Wall Systems with Antimicrobial, Chemical-Resistant Panels

- Antibacterial, Sterilizable Wall and Ceiling Panels

- HEPA/ULPA Filtration Systems for Microbial Control

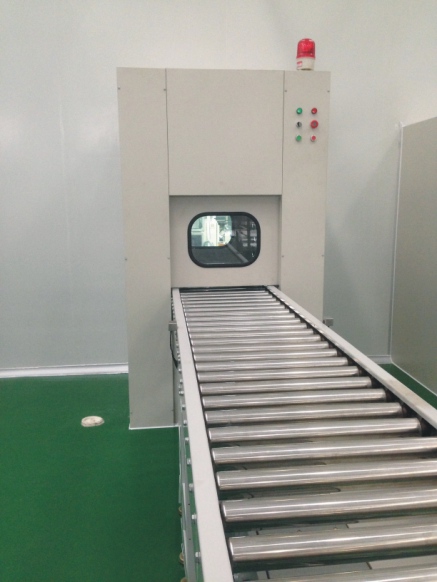

- Pass Boxes, Gowning Rooms & Air Showers

- Support for Validation, Documentation & Audits

- On-Site Installation and 24/7 After-Sales Support

FAQs – Pharmaceutical Cleanroom

Q1: What is the difference between Grade A, B, C, and D cleanrooms?

These are EU GMP classifications—Grade A is used for aseptic filling zones, while Grades B–D are for background support areas with descending cleanliness.

Q2: What ISO class corresponds to pharmaceutical cleanrooms?

Grade A = ISO 5, Grade B = ISO 6, Grade C = ISO 7, Grade D = ISO 8.

Q3: Do I need separate cleanrooms for sterile and non-sterile drugs?

Yes. GMP requires dedicated environments with separate HVAC and equipment to avoid cross-contamination.

Q4: How long is installation and validation?

Depending on complexity, 100–500㎡ installations typically take 4–8 weeks, with additional time for commissioning, IQ/OQ/PQ, and documentation.