Food Processing Cleanroom Solutions

Safe, Hygienic & Compliant Cleanrooms for the Food Industry

What Is a Food Processing Cleanroom?

A Food Processing Cleanroom is a controlled environment designed to minimize contamination risks during food production, packaging, and handling. It regulates airborne particles, temperature, humidity, and microbial load to meet hygiene standards like HACCP, GMP, and ISO 14644.

Key Benefits of a Food Processing Cleanroom

Implementing a cleanroom in your food production facility offers several major advantages:

Where Food Cleanrooms Are Commonly Used

Our Cleanroom Services & Advantages

As a leading Cleanroom Manufacturer, we provide turnkey cleanroom solutions tailored to food processing needs:

- Custom Design & Layout based on HACCP/GMP flow requirements

- Modular & Easy-to-Clean Panels with anti-bacterial surface

- HEPA Air Filtration Systems for Class 1000–100,000 environments

- Washable, Moisture-Resistant Walls & Ceilings

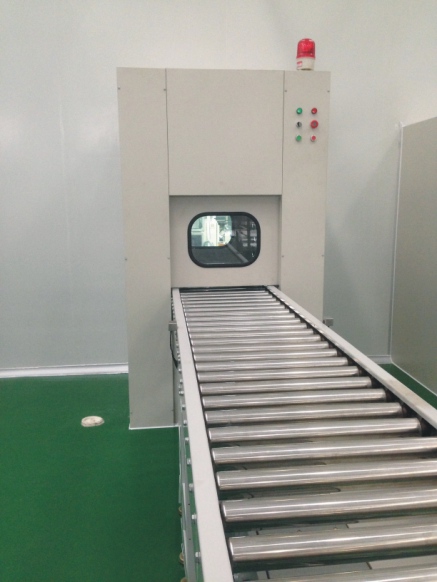

- Air Showers, Pass Boxes & Clean Booths for contamination control

- Fast Installation & 24/7 After-Sales Support

- International Delivery & Support

Frequently Asked Questions

Q1: What ISO class is required for food cleanrooms?

Most food cleanrooms fall under ISO Class 7–8, depending on product sensitivity and processing environment.

Q2: How is a food cleanroom different from a pharmaceutical one?

Food cleanrooms focus more on humidity, washability, and anti-bacterial surfaces, while pharma cleanrooms prioritize sterile conditions and particle control.

Q3: Do I need an air shower for my food factory?

Yes. Air showers reduce contamination carried by personnel and are commonly used in entrance zones.

Q4: How long does installation take?

For a 100–300㎡ cleanroom, installation typically takes 15–30 days, depending on the scope and equipment.