Recommended Equipment for Cleanroom Material Transfer 3

The core of material transfer between clean and non-clean workshops lies in blocking cross-contamination through specialized equipment. Pass-through windows, air shower pass-throughs, and PVC rapid roll-up door goods shower chambers are three common types of equipment, each with distinct technical features and applicable scenarios. These devices ensure the integrity of the clean area environment from both physical and airflow organizational perspectives, with a focus on efficient and secure Cleanroom Material transfer.

Now, let Baihong Purification recommend three types of transfer equipment for you.

1、Cleanroom Material: Pass box (basic type)

Core function: Adopting a dual-door interlocking structure (mechanical or electronic interlocking) to ensure that both doors cannot be opened simultaneously, thereby blocking direct air circulation between the clean area and the non-clean area.

Additional technical design:

(1) An ultraviolet disinfection lamp can be optionally equipped to perform microbial disinfection and sterilization on the surface of items after transfer is completed;

(2) Equipped with a high-efficiency particulate air (HEPA) filter to maintain clean air inside and prevent particulate contamination;

(3) The stainless steel box features a smooth surface that is easy to clean and is suitable for high-frequency transfer of small and medium-sized items.

2、Cleanroom Material: Air Shower Transfer Window (Enhanced Clean Type)

Upgrading technical points: Based on the transfer window, a wind shower system is added to effectively remove attached dust by purging the surface of items with high-speed clean airflow (wind speed ≥20m/s).

Collaborative design:

(1) The air shower process is interlocked with the door, and the other side door can only be opened after the air shower is completed, to ensure cleanliness;

(2) It can be paired with a 304 stainless steel conveyor belt, featuring a seamless surface that is resistant to alcohol and high-temperature sterilization. It is suitable for scenarios where high particle control is required, such as electronic components and precision parts.

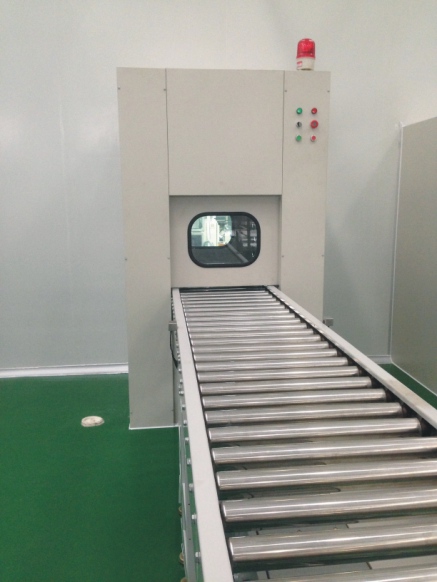

3、Cleanroom Material: PVC Fast Rolling Shutter Door Air Shower (Bulk/Batch Transfer Type)

Core technical features:

Quick opening and closing with high sealing performance: The PVC roller shutter door takes less than 0.8 seconds to open and close, and fits tightly against the door frame after closing, significantly reducing air exchange;

Double-door airlock interlock: strictly prevents both doors from opening simultaneously, equipped with an anti-pinch function to ensure no air convection during the transfer process;

Fully-covered cargo shower system: Equipped with multi-angle air nozzles, it can thoroughly shower items or cargo transfer vehicles. Combined with positive pressure control (5–10 Pa) in the clean zone, it prevents the backflow of unclean air.

Key points for use and maintenance

(1)Regularly verify the interlocking function of the equipment, keep the contact surfaces such as the inner walls and conveyor belts clean, and disinfect them on time;

(2)HEPA filters need to be replaced according to their service life (usually 6-12 months);

(3)During operation, the process of “closing one side door first and then opening the other side door” must be strictly followed to avoid human-induced damage to the clean environment.

The equipment provided by Baihong Purification, including pass boxes, air shower pass boxes, and PVC rapid roller shutter door air showers, relies on precise technical design and reliable material craftsmanship. While ensuring transfer efficiency, it minimizes the risk of cross-contamination, balances production yield and energy consumption control, and is suitable for the transfer of items in various industrial clean environments.